More than 100 years of experience with driving of electric motors has led Yaskawa to develop products which perfectly combine technical superiority with easy handling. The latest result of this evolution is the new GA500 microdrive. Compact in size and flexible in terms of motor type and connectivity they are designed to easily master nearly any application.

Simplify System Integration

GA500 drives are designed to be easily integrated into systems and machinery. By combining Network support, application focused features and great customizability with unparalleled ease of use the GA500 minimizes efforts to get your automation jobs done.

Integrated features like PLC functionality, EMC filters, braking choppers, 24 Vdc Power supply for external sensors or the Safe Torque Off circuit with SIL3/Ple eliminate external devices.

By a lower number of parts and reduced space system design is simplified while cost efficiency and system reliability increase.

Easy Operation

The GA500 comes with built-in functions and new services for a simple and time saving startup and troubleshooting without the need of studying manuals.

- Tactile keypad with multi-lingual graphical display, auto-backup, real-time clock, copy function and data logger, optional Bluetooth

- Built-in Setup Wizard for guided parameter setup without manuals

- DriveWizard Mobile smartphone app for drive setup, monitoring, guided trouble shooting with connection to Yaskawa Drive Cloud service for data backup and online documentation

DriveWorksEZ® 10 DownloadAndroid Version

- DriveWorksEZ® 10 Download iOS Version

GA500 can be programmed without any power supply connected, even while the drive is still in the box. Simply plug into one of your PC’s USB ports or any USB on-the-go device, start programming and enjoy the ease of commissioning.

Best Machine Performance

One drive for various applications

- By integrating latest motor control technology for induction, permanent magnet and synchronous reluctance motors, the GA500 drives provide best control performance at minimized energy consumption.

- Open loop zero speed and torque control of permanent magnet motors

- Run induction, permanent magnet and synchronous reluctance motors with only one type of drive

- 590 Hz output frequency

- High switching frequency for silent motor operation

- Time saving and hassle free setup of any motor without the need for Auto-Tuning

- Can be operated in up to 4000 m altitude and 60 °C hot environment

- Coated PCBs make the drive robust against dust and mist

- Designed for 10 years of maintenance free operation

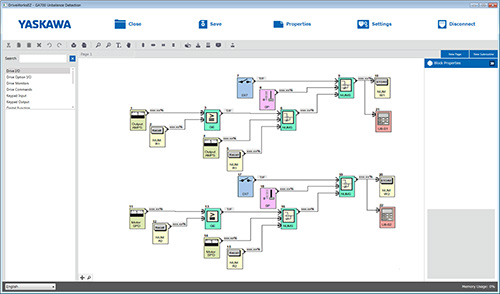

DriveWorksEZ® 10. Easy Customization

DriveWorksEZ® offers an icon-based, drag-n-drop graphical environment to add programmable functions that can tailor the drive to meet various machine and application requirements without the cost of external controllers, such as PLCs or additional controller hardware options.

- Select from 400+ function blocks like Logic/Math, Timers/Counters

- Up to 100 connections

- Offline simulation mode for testing without the risk of an application malfunction

- Protection of intellectual property with project lock

- Online monitor for visual debugging

- Fast cycle time of 2 ms, independent of program size